Page 19 of 25

Posted: Jul 15, 2011 2:12 PM

by Xenocide

You're a braver man than I. I honestly would rather hack that harness for connectors and splice em in to

one of these puppies. That harness gives me nightmares just thinking about it.

Glad to see some progress. Keep it up!

Posted: Jul 15, 2011 2:17 PM

by sbeckman7

Xenocide wrote:You're a braver man than I. I honestly would rather hack that harness for connectors and splice em in to

one of these puppies. That harness gives me nightmares just thinking about it.

Glad to see some progress. Keep it up!

It definitely crossed my mind to go that route. I'd just rather try to get it running with the OEM system to say I did it. Plus I like how theoretically adaptive the OEM is. You just can't beat the reliability and smoothness of electronics that were made to work with it.

Posted: Jul 15, 2011 2:59 PM

by davintosh

That is one massive engine/transmission. So if you're doing all OEM electronics, that means you're sticking with the slushbox too? Having three pedals under the dash would add a lot of complexity to the job, and expense.

What'cha doing with the wheels from that car? I like the look of those wheels on an e32. Too bad you're so far away...

Posted: Jul 15, 2011 5:09 PM

by sbeckman7

davintosh wrote:

That is one massive engine/transmission. So if you're doing all OEM electronics, that means you're sticking with the slushbox too? Having three pedals under the dash would add a lot of complexity to the job, and expense.

What'cha doing with the wheels from that car? I like the look of those wheels on an e32. Too bad you're so far away...

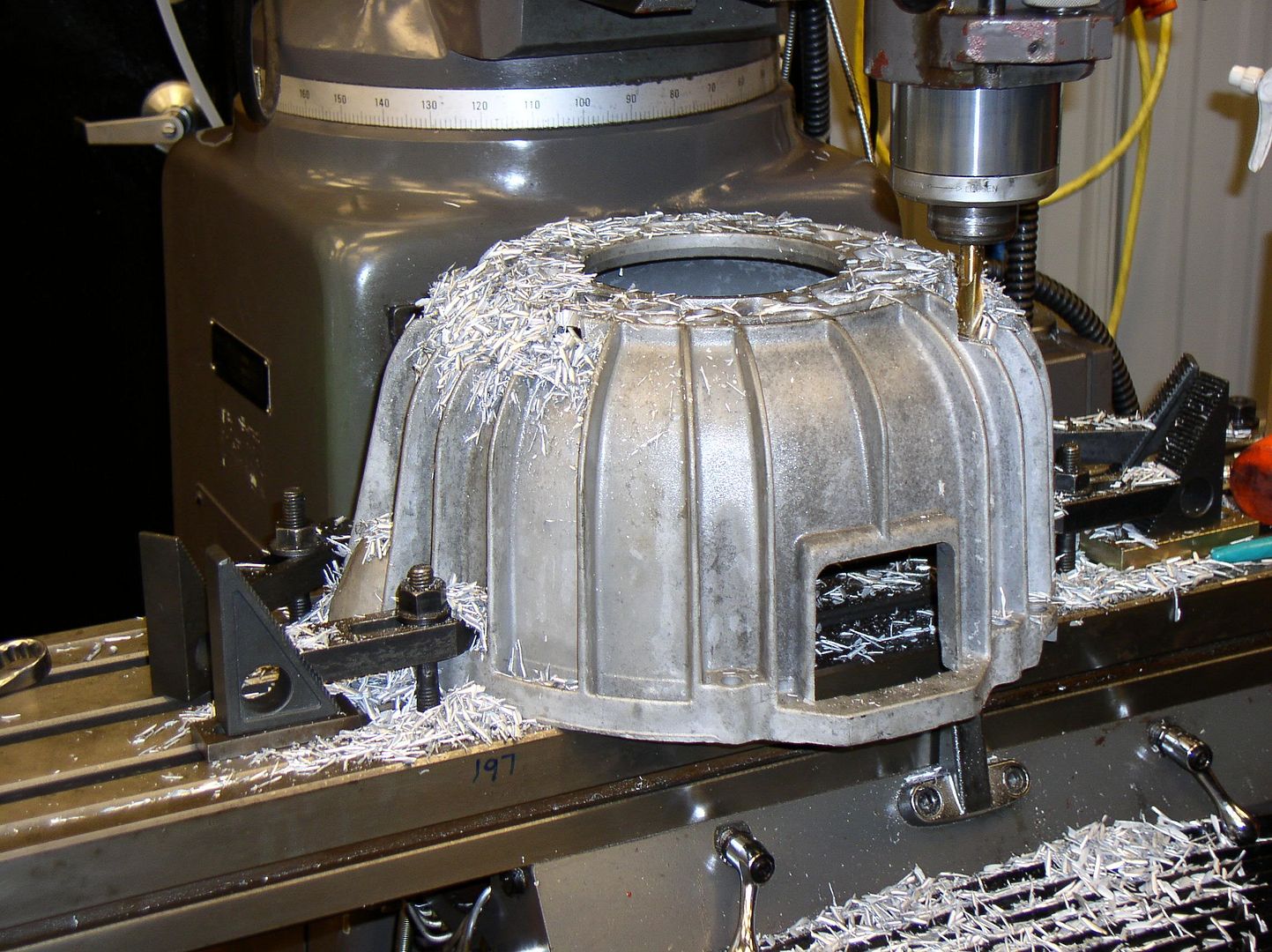

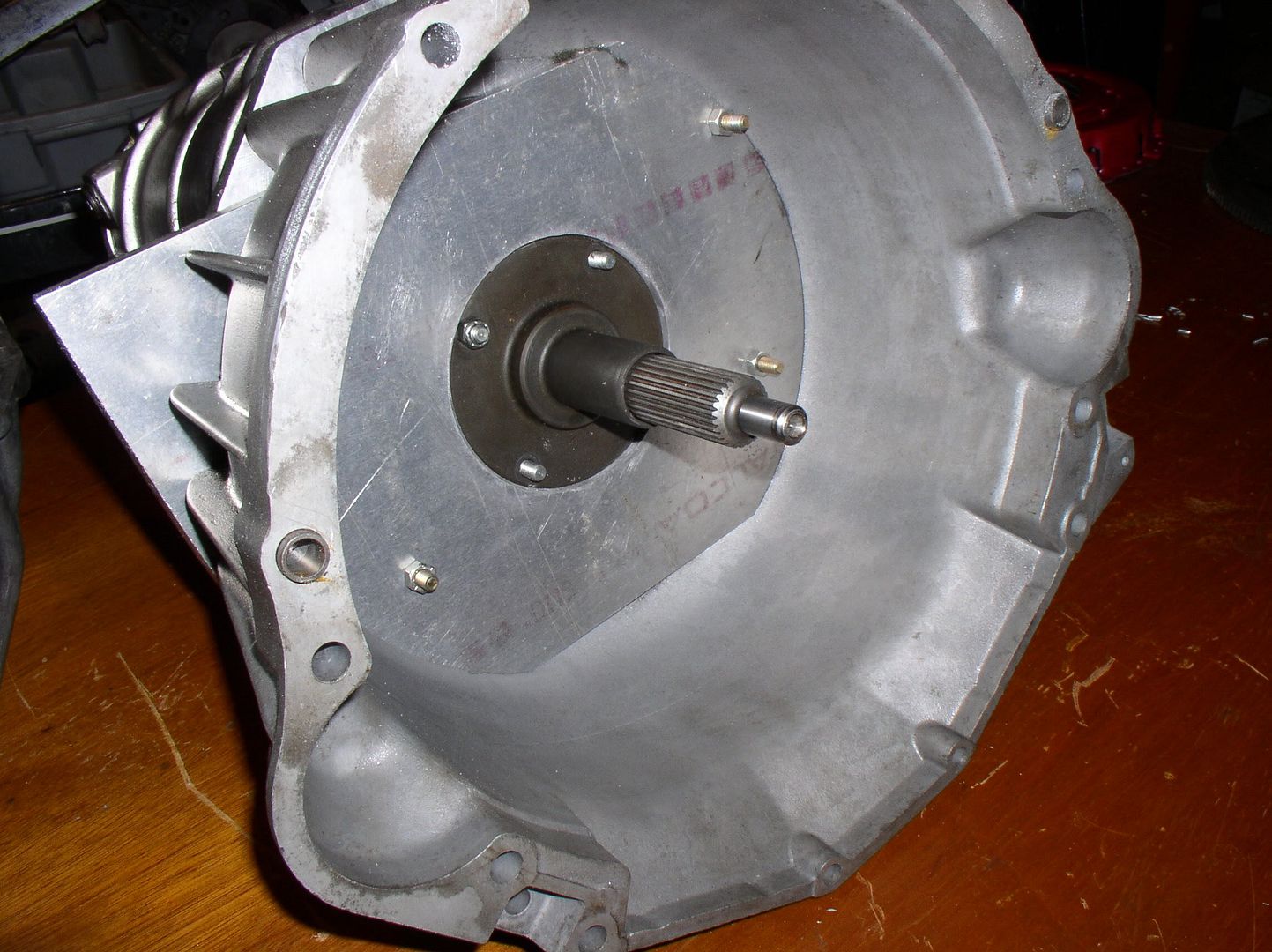

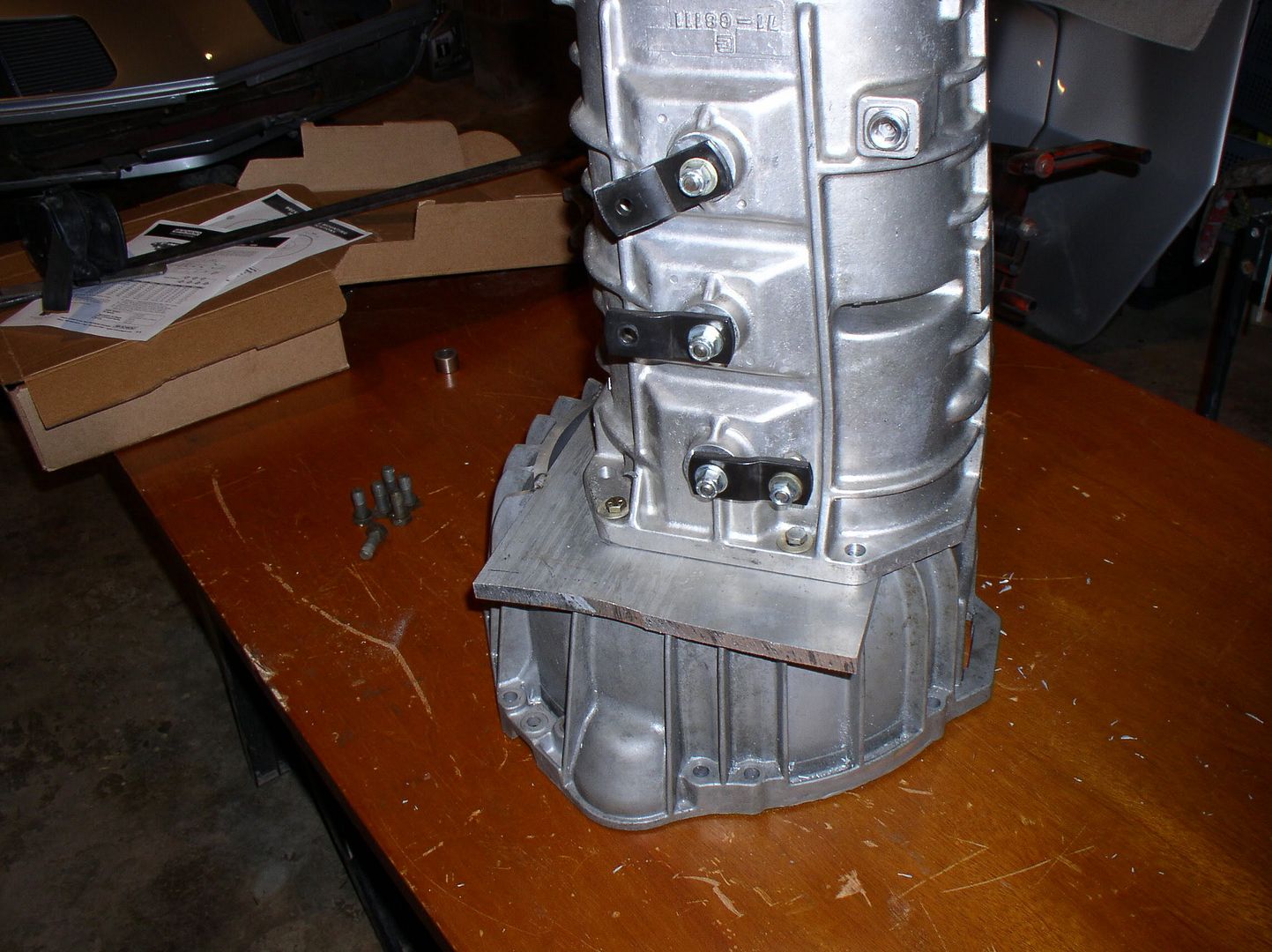

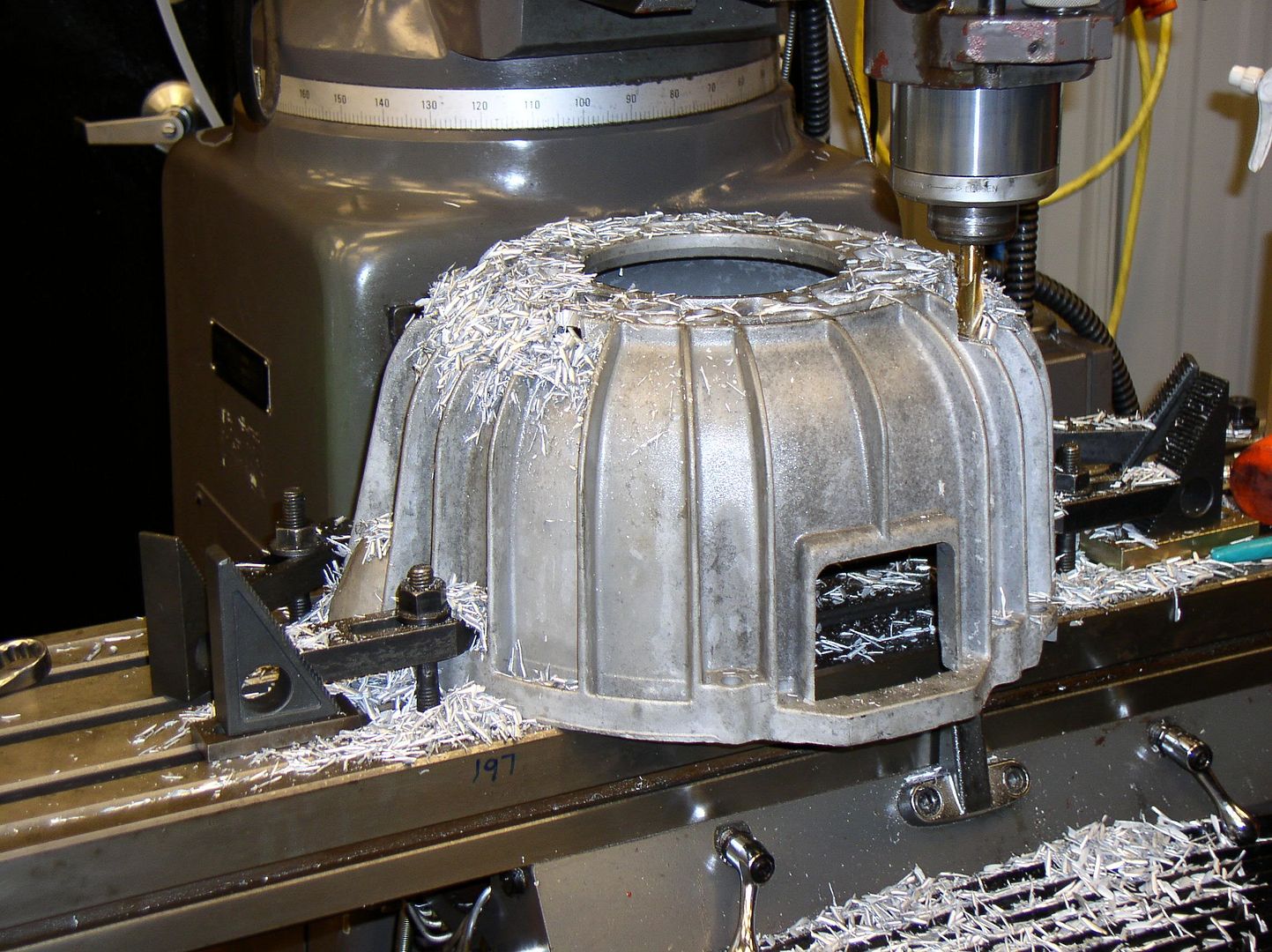

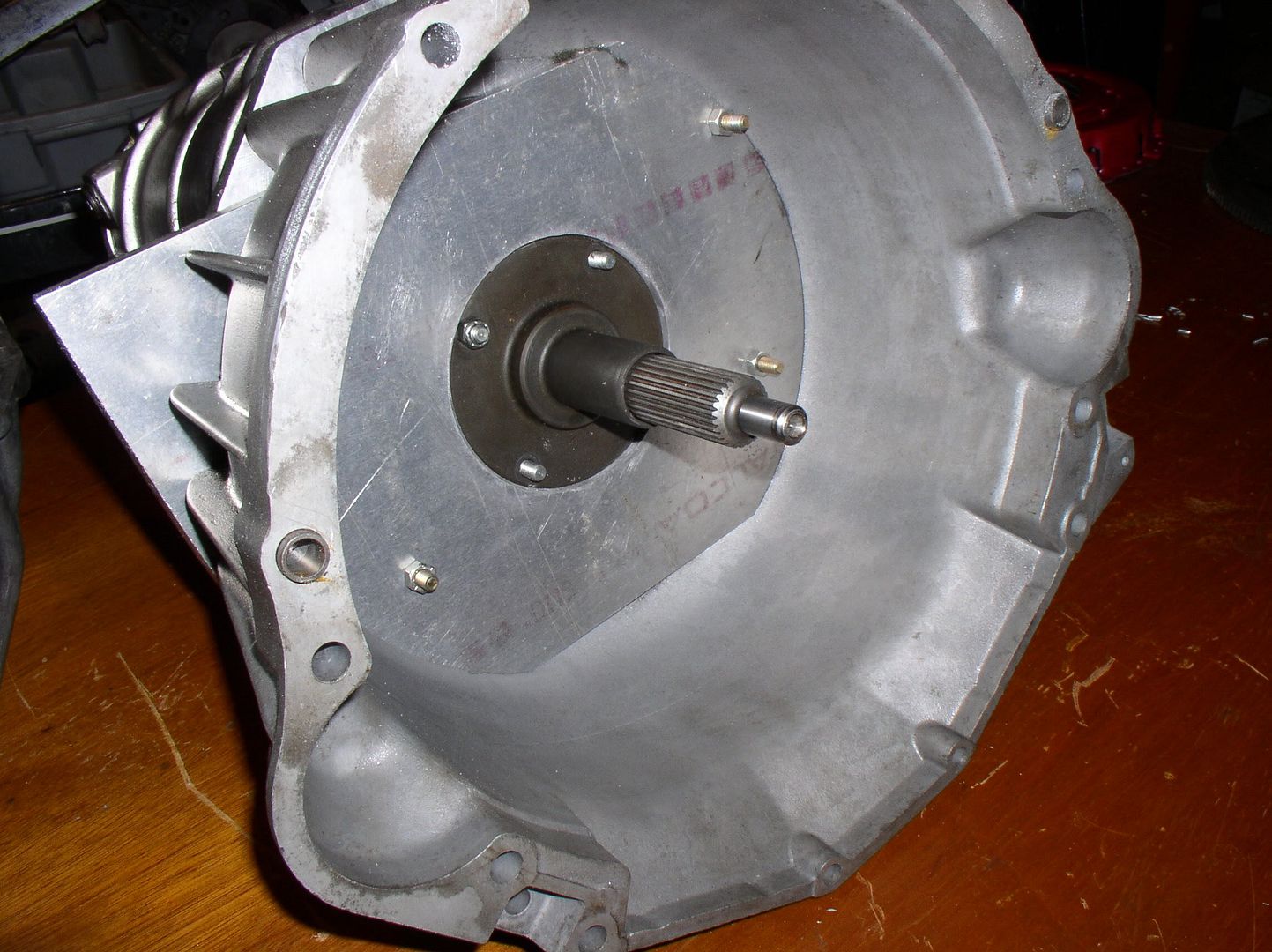

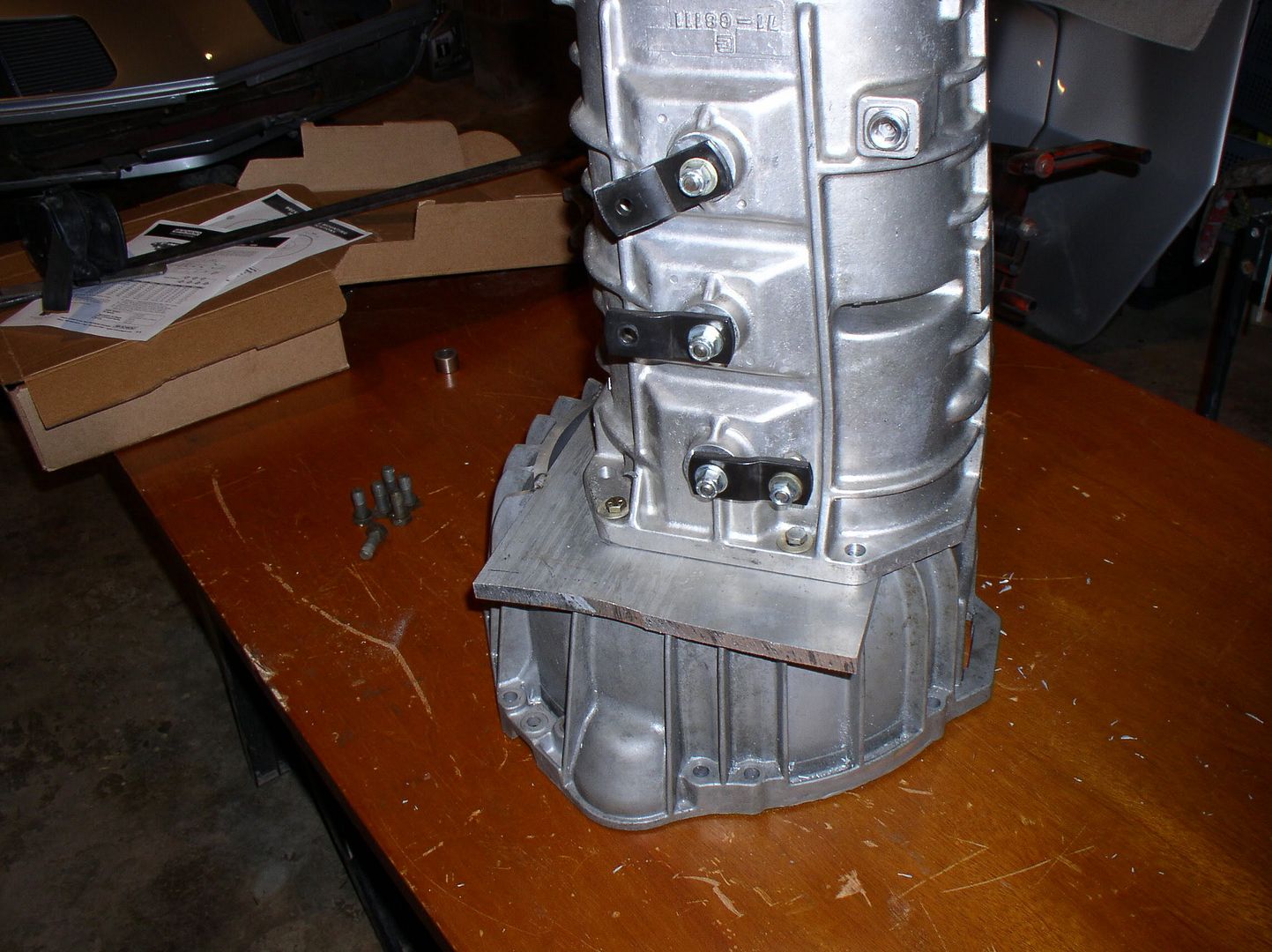

It's actually going to end up in front of the g265 I got with my e28 parts car. Since I already have it, won't add too much expenses to the project, just time and complexity since the car is wired not to run without feed from the transmission. Luckily there is a member on Bimmerforums who has done a similar conversion (with a Richmond 6 speed unit) in his '71 vette. He's been a huge help so far. For anyone that's interested as to how this is going to work, the bell housing of the automatic transmission will be modified and an adaptor plate will be machined out of aluminum, allowing me to bolt the G265 to the auto bell housing. Here are pictures of Richard's build on his vette:

I plan on doing the same thing, but with my getrag transmission.

And to answer your other question, the previous owner of the car wants the wheels back

Posted: Jul 15, 2011 5:20 PM

by Xenocide

sbeckman7 wrote:It's actually going to end up in front of the g265 I got with my e28 parts car. Since I already have it, won't add too much expenses to the project, just time and complexity since the car is wired not to run without feed from the transmission.

I'll say it again, my hat is off to you in terms of ambition, but I think you'd make life a LOT easier for yourself if you just went standalone. Are we talking simple jumpers that need moving in order to run it without the autobox? Or does the ECS need an active pulse and feedback from the transmission?

Posted: Jul 15, 2011 5:29 PM

by sbeckman7

We're talking disconnecting two wires from the tranny and connecting them somewhere else. I'm probably making it sound more intense than it is

Posted: Jul 15, 2011 5:38 PM

by Xenocide

sbeckman7 wrote:We're talking disconnecting two wires from the tranny and connecting them somewhere else. I'm probably making it sound more intense than it is

Ah, that's not as bad as I thought then. I've seen some of the honda guys go crazy trying to get their 6 cylinder engines work with a manual transmission. They make whole brain boxes for it. Even with the purpose built hardware I've seen some guys turn their ECMs into paperweights.

Posted: Jul 15, 2011 5:42 PM

by sbeckman7

Xenocide wrote:sbeckman7 wrote:We're talking disconnecting two wires from the tranny and connecting them somewhere else. I'm probably making it sound more intense than it is

Ah, that's not as bad as I thought then. I've seen some of the honda guys go crazy trying to get their 6 cylinder engines work with a manual transmission. They make whole brain boxes for it. Even with the purpose built hardware I've seen some guys turn their ECMs into paperweights.

Wow, glad my situation isn't that bad...

Posted: Jul 15, 2011 6:08 PM

by mtnman533

That is a massive engine. That's a lot of weight to be sitting on that front end, how are you going to balance the car?

Seriously awesome work, sounds like you have a good plan to make that engine work outside its comfort zone.

Posted: Jul 15, 2011 6:15 PM

by sbeckman7

mtnman533 wrote:That is a massive engine. That's a lot of weight to be sitting on that front end, how are you going to balance the car?

Seriously awesome work, sounds like you have a good plan to make that engine work outside its comfort zone.

Aside from the crank pulley, I have designed the chassis to accommodate the entire engine behind the front axle. My weight distribution should be bang on.

Almost forgot to mention I picked up something useful yesterday from the pick and pull: a power steering rack out of an e36 325i!

Posted: Jul 15, 2011 8:25 PM

by mtnman533

sbeckman7 wrote:mtnman533 wrote:That is a massive engine. That's a lot of weight to be sitting on that front end, how are you going to balance the car?

Seriously awesome work, sounds like you have a good plan to make that engine work outside its comfort zone.

Aside from the crank pulley, I have designed the chassis to accommodate the entire engine behind the front axle. My weight distribution should be bang on.

Almost forgot to mention I picked up something useful yesterday from the pick and pull: a power steering rack out of an e36 325i!

Ok sweet, so like a Caterham it'll be mid-front engined, very cool!

Posted: Jul 18, 2011 3:20 PM

by sbeckman7

Got 98% of the wiring harness out on Saturday! All that's left is the wires going to the tank, which I'll drop at shop tonight. After that I take out the master cylinder, door parts, semi-trailing arms, possibly shocks, and wheels, and call it done! Will update pics once I get home and have internet that isn't slower than dial up...

Posted: Jul 19, 2011 3:32 PM

by sbeckman7

Car is back home. Pick n Pull will take it away later this week.

the small part of the wiring (dash, obc, lights, etc):

The big part (ECU's, EML, main fuse box, relays, etc):

[/img]

Posted: Jul 21, 2011 4:20 AM

by sbeckman7

What's new:

- I bought a hoist

- Engine and everything else is home (including the parts car)

- Got a generous quote from Pick n Pull to pay me for the car shell

- Wasn't able to get suspension body-mount dimensions from Ireland Engineering so I'm at a bit of a standstill with mounting the control arms

- On the hunt for an M70 manual flywheel and clutch kit

- Wondering what I should do with the engine in the meantime (dissasemble? clean? rebuild?)

If anyone is wondering why I'm focusing on the drivetrain right now and not the frame, it's because I have zero space to work on the car in my [parents] garage. We're slowly clearing it out but it will take some time, so I'm keeping myself busy with what I consider to be the most exciting part of any car.

same crank bolt pattern as the M60

huge fan of the remote oil filter and cooler

my view coming home

tucked into the garage next to the m30

G265 bell housing (left) vs. M70 auto (right)

difference in height: to offset this I'll need to machine down the M70 bell housing (so it's the same height as the getrag one) and then bolt the G265 to it via an aluminum plate welded to the modified bell housing.

Tomorrow I'm hoping I'll have time to do an electrical mock up

Spencer

Posted: Jul 28, 2011 11:44 PM

by sbeckman7

The closing of another chapter:

Timing constraints meant the Pick n Pull couldn't take the car away before we left for our two week vacation back east, so I didn't get paid for it. On the plus side, I didn't have to pay to have it removed by a local tow company. I was able to get everything I needed while selling parts from it at the same time, with hopes of breaking even on the original cost. The following video is me explaining what I’m using it for. It was obviously meant for a different target audience (relatives and friends), but this is what it looks like:

http://www.youtube.com/watch?v=Ov1kkkh9DE4

Spencer

Posted: Aug 02, 2011 7:11 PM

by sbeckman7

Posted: Aug 09, 2011 7:27 AM

by Cl1n7R1X

Great work so far mate. Love what you're doing and enjoying reading the progress.

Since you're hooking up a manual to that box is there any chance you could send me the Auto gearbox harness? A mate of mine got a LPG system installed and they torched his wiring. Been trying to find one here in Australia but they're alot harder to find. PM me if you can help me out :D

Posted: Aug 21, 2011 1:18 PM

by sbeckman7

Update:

Not much has changed, although now I have a definitive starting time to begin on the metal work of one month from now (that's when my friend will be done needing a welder). In the mean time, there's plenty to do with making space in the garage, ordering metal, figuring out engine placement, and figuring out if I am going to use this honeycomb sandwich panel stuff for the floors as suggested by moosehead. Hopefully I will be able to!

Posted: Sep 18, 2011 2:44 PM

by sbeckman7

Got the welder home, continuing to take engine apart. Making more space in the garage. So far everything is going as planned

Posted: Sep 27, 2011 4:02 AM

by sbeckman7

Posted: Sep 27, 2011 11:44 AM

by Tammer in Philly

sbeckman7 wrote:

Worked out pricing for a set of (7) VDO gauges. Includes 220mph speedo (the next smallest was 160 and that's not happening), 7k tach, oil temp, oil pressure, water temp, fuel, and clock. Don't need a voltage display as the OBC can do that, and I don't really need the clock but its 30 bucks and looks nice.

220 mph speedo? Are you gonna put a huge Pep Boys wing on the back and some neon lights, too? Even if it's possible, theoretically, to do 200 mph in that thing, you never will. There is no track where you will break 155 mph, and it will have all the aerodynamics of a brick. Worse, it will probably be very unstable north of 140-150 mph. I'm not trying to be harsh, but you're using a 1950s-inspired body shape with no aero development whatsoever and eyeballing an attractive form. For a home-brew car, that's absolutely great, but don't expect it to be drivable at 150+, and don't expect it to accelerate well past 110 mph. At 100+, acceleration has nothing to do with power-to-weight and everything to do with power-to-drag. Look at a Caterham, weighs less than a chimp's nutsack and can't break 120 on a long straight.

With a 160-mph speedo, the gradations will actually be visible at a glance. A 220-mph speedo is just antlers. Ditch it.

Also, you're keeping the OBC? Why have all that wiring? Oil pressure, oil temp, water temp, voltage--that's all you need to know about the engine. Maybe EGTs or AFRs if you want to get crazy, but without boost it's not too critical. If you're running factory engine harness, then the OBC is no big deal, but if you ever move to standalone you should ditch it, too.

BTW, I'm thrilled that you're still making progress and I want you to hurry up and get the engine mounted!

-tammer

Posted: Sep 27, 2011 2:35 PM

by sbeckman7

Tammer in Philly wrote:sbeckman7 wrote:

Worked out pricing for a set of (7) VDO gauges. Includes 220mph speedo (the next smallest was 160 and that's not happening), 7k tach, oil temp, oil pressure, water temp, fuel, and clock. Don't need a voltage display as the OBC can do that, and I don't really need the clock but its 30 bucks and looks nice.

220 mph speedo? Are you gonna put a huge Pep Boys wing on the back and some neon lights, too? Even if it's possible, theoretically, to do 200 mph in that thing, you never will. There is no track where you will break 155 mph, and it will have all the aerodynamics of a brick. Worse, it will probably be very unstable north of 140-150 mph. I'm not trying to be harsh, but you're using a 1950s-inspired body shape with no aero development whatsoever and eyeballing an attractive form. For a home-brew car, that's absolutely great, but don't expect it to be drivable at 150+, and don't expect it to accelerate well past 110 mph. At 100+, acceleration has nothing to do with power-to-weight and everything to do with power-to-drag. Look at a Caterham, weighs less than a chimp's nutsack and can't break 120 on a long straight.

With a 160-mph speedo, the gradations will actually be visible at a glance. A 220-mph speedo is just antlers. Ditch it.

Also, you're keeping the OBC? Why have all that wiring? Oil pressure, oil temp, water temp, voltage--that's all you need to know about the engine. Maybe EGTs or AFRs if you want to get crazy, but without boost it's not too critical. If you're running factory engine harness, then the OBC is no big deal, but if you ever move to standalone you should ditch it, too.

BTW, I'm thrilled that you're still making progress and I want you to hurry up and get the engine mounted!

-tammer

There you go again Tammer, injecting harsh reason into my otherwise loopy build method

You do have a valid point on the speedo. But it's actually not that different (in terms of increments) to the 160mph speedo. In fact the increments are actually easier to see at a glance due to the number spacing. Here are the two to compare:

You should also know that the 220mph speedo has a 4 inch diameter, whereas the 160mph speedo only comes in 3 3/8 inch diameter. And they cost the same amount. Besides, maybe I'll get past 160 with a 600hp twin turbo setup on the salt flats

As for the OBC question, yep, I'm keeping the oem wiring harness and engine management. If you go back a few posts you'll see a large picture of my wiring harness along with a youtube video that explains it all. Another big plus of the OBC is the ignition code, ideal for a car that will have no windows or door locks. Just in case. Thanks for your constructive criticism buddy

Spence

P.S. If you know where to get neon lights and a sweet wing, PM me. I need this thing to go as fast as possible.

Posted: Sep 27, 2011 2:49 PM

by Tammer in Philly

Okay, I accept your reasoning. Salt flats are a consideration. Don't die.

So OBC w/ stock engine harness is cool. When you go twin-turbo, though, that's not gonna work for you. I'm just planning ahead (and spending your money).

For all the go-fast bits, check

this place out. Glad to help!

-tammer

Posted: Sep 27, 2011 2:54 PM

by sbeckman7

That link is heaven! I think I'll get one of everything and see what I can fit on.

True on the turbo stuff, but no reason to get a standalone system now. That said, I will be getting an appropriate head gasket set for turbo pressure.

Posted: Sep 28, 2011 3:43 AM

by sbeckman7

I'm just gonna go ahead and post these up now - The next phase of the project, to build this:

This is the final design for the frame. Slightly overestimated numbers are as follows:

Total Square Length: 923.75”

Total Round 1.5” length: 883.5”

Main Frame Rails: 205.37”

Square Tubing Weight: 139.75 lbs

Round 1.5” Tubing Weight: 105 lbs

Roll Bar: 23.5 lbs

Shock Mounts: 10 lbs

Main Rails: 80 lbs

Total Frame Weight: 358.25 lbs

I designed the frame in CAD with each piece of metal having some overlap just to be on the safe side of weight and length dimensions. This weight could increase by up to 40 lbs once I find out what specific sizes Tube Service Co. has in stock. If there is no option between .095 and .120, I'm going .120". It can't hurt.

Posted: Sep 29, 2011 5:55 PM

by mtnman533

I'm looking forward to seeing this thing on scales... For example, my caterham when I got it (empty, just frame work, body panels, other small odds and ends) was a solid 400lbs, 2 people can carry it, but 3's better. And the car when fully laden

with a full tank of gas is 1,157lbs (525kg).

This is much bigger... Just seems to me that the weight estimate is a little on the low side is all. I may be totally wrong of course, it's hard to tell from just drawings. I do remember making things in metal shop with similar material and having it be surprisingly heavy at the end... Out of curiosity, have you weighed the to frame rails that you have now? That would lend an idea as to what the final weight will be.

But I really do like the progress, I really look forward to the finished product!

And the caterham superlight series all reach over 130mph, the R500 does 160+

, just so you guys know...

Posted: Sep 30, 2011 8:17 PM

by sbeckman7

Wow, some interesting stuff right there mtnman. Thanks for those numbers! It's nice to be able to compare it to something. I agree with you that it's very hard to get an accurate number just from drawings etc., but here is the quote from Tube Service Co. for the materials. This should shed some light on the numbers. And I got plenty of extra for when I mess up

I'm using less than 80 ft of each (they come in 20ft sticks).

--------------------------------------------------------------------------------

SQUARE STEEL TUBE HREW

5 PCS

266 LBS

1-3/4" X 1-3/4" X .120 WA X 240.0000"

100 FT

MATERIAL

100 FT @

2.7400 FT

274.00

DELIVERY CHARGE

20.0000 LOT

20.00

--------------------------------------------------------------------------------

3 ROUND CARBON STEEL TUBE DOM-SRA

5 PCS

177 LBS

1-1/2 OD X .120W 1.260 ID X 240.0000"

100 FT

MATERIAL

100 FT @

2.7900 FT

279.00

DELIVERY CHARGE

20.0000 LOT

20.00

Here is what I'll be starting on once I get my materials!

It's so nice having Inventor on my mac finally thanks to Bootcamp!

Posted: Oct 01, 2011 2:24 AM

by mtnman533

Awesome! It'll be quite light for its size, and I'm glad I was proved wrong

.

Posted: Oct 01, 2011 12:54 PM

by sbeckman7

Yes I was quite surprised myself to see how light the materials are for a car of this size. It is by no means small

That said, I accidentally showed the wrong square steel quote, for .090 instead of .120 wall. I have fixed that. The .120 was only 2 cents more and will add another 40lbs to the frame weight. I am fine with that for the added strength it will bring. The entire car is now built beyond SCCA roll cage thickness specs for its weight class.

Posted: Oct 01, 2011 1:16 PM

by mtnman533

Awesome man, that's good, strong is definitely worth the weight when you have the ability to add power to counter act it.

What are your thoughts on end weight? Looking at, what 1500lbs?

[/img]

[/img]